Walls - Products and Systems

Single Wythe Architectural Walls - A single wythe precast concrete wall panel, also referred to as an architectural precast concrete panel, consists of a single concrete layer that is designed to have the architectural features and the structural integrity to withstand the applied loads. Single wythe panels can be used as non-insulated walls for unheated spaces such as warehouses or parking structures but can also be insulated from the inside to provide a complete building enclosure assembly or other protection systems onsite. The thickness of the wythe can vary based on the applied loads and other design requirements but is typically more than 75 mm using regular strength concrete. Thinner sections are possible with higher strength concretes.

Double Wythe Precast Concrete Insulated Wall PanelsA double wythe precast concrete insulated wall panel, also known as an "insulated panel" or "sandwich panel," features a layer of insulation between two concrete wythes. The exterior wythe, with architectural features, is at least 75 mm thick, while the interior structural wythe ranges from 170 mm to 350 mm thick. Typically, extruded or expanded polystyrene is used for insulation, but other options with similar or better thermal properties are available.

Wythes are connected with shear ties and can be:

- Non-composite: Each wythe resists loads independently.

- Fully composite: The panel acts as an integrated system with no slip between wythes.

- Partially composite: Transfers only part of the shear forces needed for full composite behavior.

Precast concrete wall panels are the preferred wall system for mid- and high-rise buildings for their ability to accelerate construction, reduce costs, and enhance performance.

Sound Walls: Precast concrete sound walls are one of the most effective solutions to mitigating road noise for communities living near highways and busy traffic areas. In addition to their robustness and durability, precast concrete sound walls also offer several advantages:

- Precast concrete sound walls due to their mass provide a superior noise transmission-loss value compared to other systems;

- Architectural finishes can be endless by combining color additives, stains, and textured formliners;

- A structurally robust wall system that requires a significantly smaller footprint than other noise-reduction methods;

- A cost-effective system and durable long-term solution compared to other materials;

Retaining Walls: Precast concrete is an ideal solution for reinforcing and preventing soil erosion. A Mechanically Stabilized Earth (MSE) precast concrete system is a durable retaining wall designed to bear heavy gravity and lateral loads. The exposed side can be customized with various architectural finishes. MSE panel wall systems feature interlocking precast concrete panels supported by grids that extend into the retained soil, creating a reinforcing zone behind the wall.

Another method is using modular block systems, where individual precast blocks interlock to form a retaining wall. The main advantages of precast concrete retaining walls over conventional reinforced concrete walls are ease of installation, durability, and faster construction.

Walls

Walls

Floors

Floors

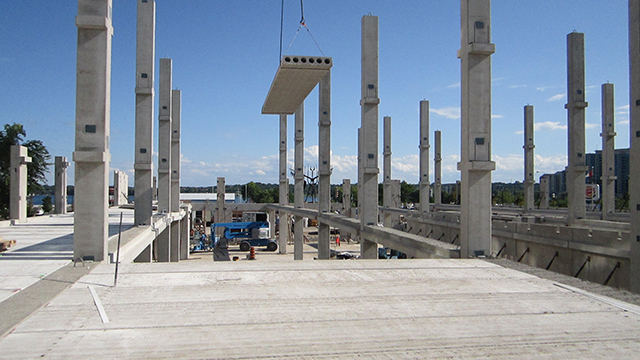

Parking Structures

Parking Structures

Infrastructure

Infrastructure