Infrastructure - Products and Systems

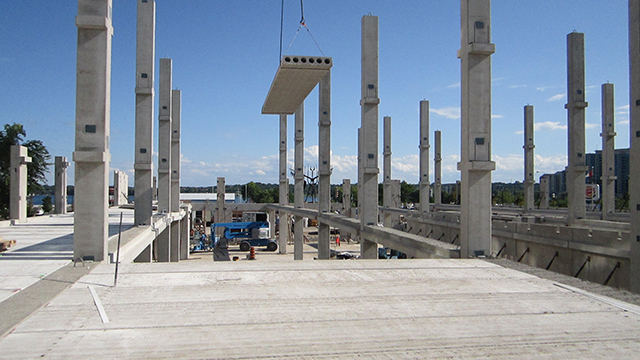

Bridges: Precast concrete Accelerated Bridge Construction (ABC) is a construction methodology that uses state-of-the-art planning and design, innovative materials, smarter procurement, and advanced construction methods to reduce the time and effort it takes to build new and replace or rehabilitate existing bridges. Precast bridge products require minimal lead times because they are locally manufactured in standard shapes and sizes. Each operation in the manufacturing process provides an opportunity for inspection and quality control.

Aside from the superior quality, precast concrete elements significantly reduce the onsite construction schedule, the overall cost, and minimize road closures and traffic interruption for bridge construction. The precast components are easy to erect in any weather. Simple connections join the superstructure to the substructure to create a long-lasting durable structure. The following are common precast concrete standard products used for bridges:

- Bridge Decks: partial or full-depth

- Girders: various shapes including NU, CPCI, slab, box, and other regional standard types

- Piers and pier caps

- Approach slabs

- Abutments

- Footings

- Retaining wall panels

Traffic Barriers: Precast concrete barriers offer superior performance compared to alternative systems including elevated resilience, durability, low maintenance, and higher design compatibility with roadways and highways, urban environments, and architecture.

There are different types of precast concrete barriers including:

- Low Profile Barriers

- Transition Ends

- Mini Barriers

- Tapered Barriers

- F-shape Barriers

- New Jersey Barriers

- Full Barriers

- Traffic Calming Curbs

Utility Modular Buildings: Modular precast concrete buildings are ideal for communications and power shelters as they are highly customizable with cable racks, trays, electrical systems, static grounding wires, etc. to meet your exact specifications. Precast concrete above-ground vaults are also perfect for communications, electrical, gas or other methods, as they protect the vital connections and controls for utility distribution. These structures are easily installed, moveable, provide excellent durability, have long service life, and are climate resistant. There is a wide range of applications for precast modular utility structures including restrooms, ticket booths, security shacks, pool facilities, maintenance workshops, pump houses, shelters, storage and more.

Poles: Precast concrete poles are commonly used mainly for their versatility, durability, and speed of installation. Precast poles can save erection time and money by eliminating the need for anchor base structures which may take days or weeks to install. A precast concrete pole, under most conditions, can be set in hours (drill a hole, place the pole, backfill with crushed aggregate, concrete or the original soil, then finish off with concrete or sod). This process eliminates unsightly base plates, studs or nuts that are normally used with steel poles.

Below Grade: precast concrete is a perfect choice for below-grade applications. The high-performance concrete provides great resistance to ground waters, freeze and thaw cycles, salts, and other chemicals to which these structures are usually exposed. There is a wide range of standardized precast concrete products for below-grade usage including the following:

- Culverts

- Manholes & Vaults

- Tunnel liners

- Pipe

- Electrical boxes

- Drainage & Trenches

- Tanks

- Oil Interceptors

- And many more

Walls

Walls

Floors

Floors

Parking Structures

Parking Structures

Infrastructure

Infrastructure