Architectural Finishes - Products and Systems

Precast concrete's versatility in color, form, and texture, combined with the benefits of durability and efficiency, make it the best choice for a wide range of architectural projects. Precast concrete can offer a wide variety of finishing techniques when combined with materials like aggregates, sand, cement, pigments, paints, form liners, stains, and brick and stone veneers. This flexibility allows for achieving diverse design objectives with countless colours and textures.

Versatile Finishes: Precast components can feature a range of shapes and finishes, from smooth structural units to elaborate architectural treatments. Using techniques like sandblasting and chemical retarders, rich, textured surfaces can be created by exposing coloured sands, aggregates, white cement, and coloring agents. Custom form liners and coloured stains can introduce reveals, patterns, and other architectural effects. Additionally, stone, tile, brick, and other materials can be cast into precast panels, offering the luxurious appearance of stone at a fraction of the cost:

- Formliners: These provide a simple solution to add detailed, high-quality textures to concrete. They come in hundreds of standard textures or can be custom designed to create unique patterns, such as leaves, fossils, or cultural icons.

- Photo Engraving: This technique turns façades into canvases. Images are converted into files for CNC cutters, creating relief patterns that cast shadows and bring the images to life in concrete.

Colour and Stains: Colour can define form, shape, and space. Paints and stains can be applied to precast concrete at the plant or on-site, making it possible to blend additions, preserve historical landmarks, or create modern designs.

Brick and Stone Veneers: Brick-faced panels combine the structural benefits of precast concrete with the aesthetic appeal of clay masonry, without the time and cost of on-site bricklaying. Stone veneer-faced panels offer several advantages:

- Thinner veneer sections due to closer anchoring points

- Economic assembly of complex units like column covers and window frames

- Faster enclosure for earlier trade work and occupancy

- Ability to span column-to-column, reducing floor-edge loading and eliminating the need for temporary scaffolding

Walls

Walls

Floors

Floors

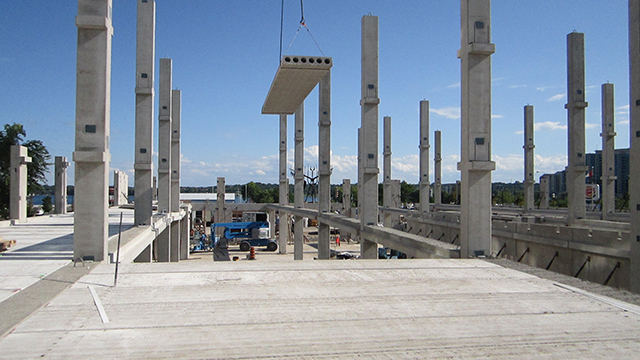

Parking Structures

Parking Structures

Infrastructure

Infrastructure