Expertise and collaboration deliver a compelling architectural award winner

By Venelin Kokalov

Simon Fraser University’s new, five-storey Sustainable Energy and Engineering Building (SE3P) in Surrey, BC represents the University’s first major step in expanding beyond its Central City campus to become a distinct academic precinct within Surrey’s growing and revitalized City Centre neighbourhood. Funded in part by the Federal Government’s Post-Secondary Institutions Strategic Investment Fund (SIF), this distinctive 16,000 square metre (173,000 square feet) facility is purpose-built to house the new Sustainable Energy and Engineering (SEE) program which offers an integrated, multi-disciplinary approach to energy engineering education to support the clean tech, renewable and sustainable energy sector.

With a building program organized around a light-filled central atrium and sweeping staircase punctuated with trees at varying levels, SE3P comprises teaching and research labs; collaboration and study spaces; faculty, graduate and administrative offices; recreational rooms; undergraduate and graduate lounges, student services, and plant maintenance facilities. Approximately 515 students and 60 faculty and staff will use the building, and its 400-seat lecture hall, situated on the southwestern portion of the ground floor, will serve the full SFU Surrey campus as well as the broader Surrey community.

The project’s fast-track delivery method necessitated a significant overlap in the design and construction phases. Utilizing prefabricated precast concrete elements for the façade became a key consideration, not only for ensuring long-term durability and reduced maintenance, but because it also enabled the building to be closed in quickly to meet the tight construction schedule.

As a result, SE3P’s compelling architectural expression is a unique façade composed primarily of framed alternating strips of energy-efficient, undulating precast concrete double wythe insulated panels and reflective glazing.

Drawing inspiration from the geometric pattern of electrical circuit boards, the precast concrete panels also symbolize the technological subject matter that will be taught within the building.

By fabricating the exterior finish, thermal and moisture protection, and interior finish off-site as a single pre-assembled system, the project’s schedule, performance and energy-saving goals were maintained while mitigating on-site construction noise and debris. The heavier precast concrete elements with reflective glazing help to animate the façade and are juxtaposed with the transparent glazing at the building’s ground plane which extends the outdoor public realm into the interior public space, engaging the local community.

SFU’s Sustainable Energy and Engineering Building is targeting LEED Gold certification and creates a stunning landmark in Surrey’s City Centre.

Venelin Kokalov is Design Principal at Revery Architecture Inc.

Precast concrete masters the wave

By Zoran Stanojevic

The building is the home of the first sustainable energy engineering program in Western Canada, and so its design highlights the relationship between energy, the environment and engineering.

|

|

|

The façade flows with white precast concrete and glass walls, evoking a circuit board, while allowing sunlight to nurture an indoor garden, creating a bright and beautiful learning environment. The stunning precast pieces are textured with a wave-patterned surface, a technically difficult finish when working with unforgiving white concrete.

To achieve this level of finishing, the General Contractor Bird Construction engaged SureClad Concrete Ltd., a subsidiary of Surespan Structures Ltd. and a member of the Surespan Group of Companies, to fabricate and install the precast concrete elements for the façade.

Production Flow

This project offered a fresh challenge to the team of specialists which has over 20 years of experience constructing buildings, parkades, marinas and bridges. Surespan is certified to CSA/CPCI through the CPCQA Certification Program.

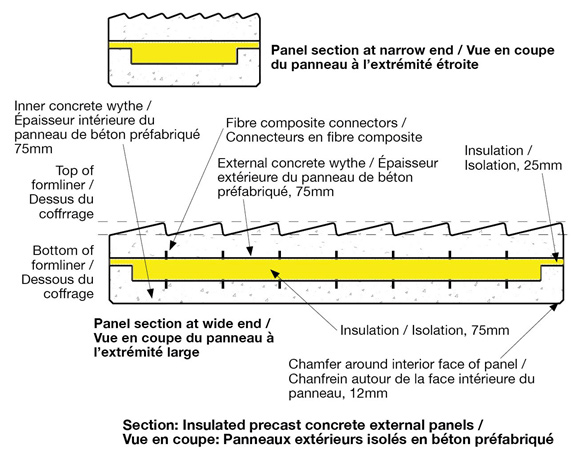

SureClad’s role was to provide and install 736 white precast concrete façade and canopy pieces representing 335 insulated precast concrete cladding panels 225mm thick (9 inches), representing 1,423 square metres (15,317 square feet); and 401 precast concrete canopy panels 75mm thick (3 inches), representing 1,283 square metres (13,810 square feet). The cladding panels consisted of curved and rectangular panels designed to be cast on six different formliner profiles.

While SureClad has a full-sized batch plant onsite, for this project a dedicated low-volume batch plant was procured and modified to produce multiple small batch loads of white concrete. This ensured minimal waste, optimum quality control, and accommodated insulation and stressing during production.

Production and installation of the precast concrete components was completed over the a five and a half month period from December, 2017 to early June, 2018.

Engineering Expertise

The project funding was contingent on an expedited schedule. Design-assist of the cladding was part of the scope and SureClad invited Kassian Dyck & Associates (KDA), a leading precast concrete design consultant in Canada, to join the team. During design-assist, KDA worked directly with SureClad and Revery Architecture Inc. to deliver a constructible product that met the Owner’s aesthetic and functional vision. Additionally, KDA helped SureClad with the precast concrete design, drawings and methodologies for producing, storing, shipping and rotating/erecting pieces with unusual shapes onto the building.

One of the design challenges was managing the fragile ‘necks’ and wythes of concrete on long pieces. KDA worked with SureClad and designed the architectural pieces to be prestressed to reduce the potential for visible cracking across the wave patterns and to provide additional strength and stability while handling the pieces.

Collaborating with industry partners

For this project, SureClad collaborated with several suppliers for assistance. US Formliner supplied a Nawkaw/Reckli formliner to produce the expanding and contracting wave pattern on the cladding panels. We worked together to get a uniform finish and colour, avoiding any deviations in appearance that would detract from the clean appearance of the vertical multi-faceted waves on the panels.

To produce the striking white face, SureClad teamed with Coloured Aggregates to provide sand from Ontario, Lehigh Cement Company for cement from Mexico, and local supplier Butler Brothers for aggregate. The combination of sparkling white sand, bright white cement powder and the muted grey aggregate allowed for added depth while still providing a dazzling white surface.

The more practical aspects of creating variably shaped pieces to attach to the building and provide cladding and insulation support required the assistance of :

- Thermomass for its insulation and panel wythe system to reach an R-value of R-15,

- JVI, Inc., Dayton Superior and National Concrete Accessories for connection and forming components,

- Richform/JK Thermal provided an invisible white connection strip, Tigerloc, as a nailer strip, and

- Surespan Construction Ltd., another member of the Surespan Group of Companies, provided installation services.

An award-winning result

Revery Architecture Inc. won the Canadian Precast/Prestressed Concrete Institute’s 2018 Roy Willwerth Architectural Recognition Award for its precast concrete façade design of the project. The award recognizes outstanding contributions to the Canadian precast prestressed concrete industry in architectural design, sustainability, innovation and change; for positive leadership, industry altering development and expansion; and for accelerating the growth of the Canadian precast prestressed concrete industry from within the architectural and design communities.

- OwnerSimon Fraser University (SFU)

- ArchitectRevery Architecture Inc.

- Precast SupplierSurespan Construction Ltd.

- ContractorBird Construction

- Structural EngineerKassian Dyck & Associates

Imagineering Magazine

View our latest issue of the popular Imagineering Magazine.