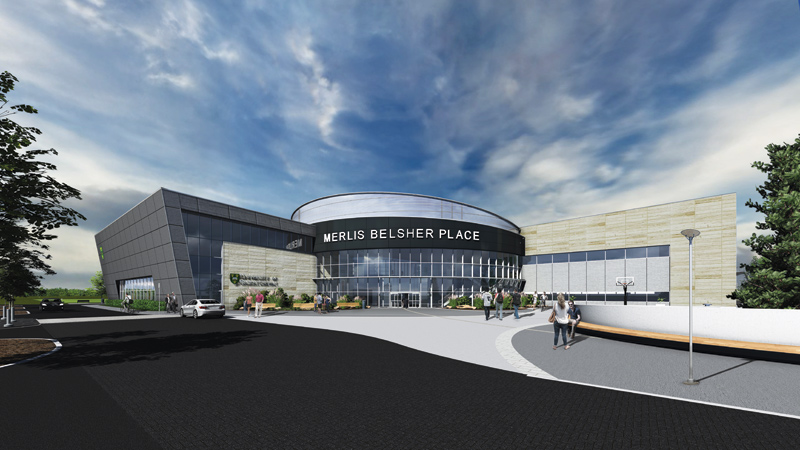

Integrated design delivers robust building for campus and community

By Dallas Huard

Merlis Belsher Place is a twin-ice, multi-sport facility located on the University of Saskatchewan campus in Saskatoon. Home of the University of Saskatchewan Huskie hockey, basketball, soccer, and campus leagues, as well as the Midget AAA Contacts and Midget AAA Stars of the Saskatoon Minor Hockey Association, its two ice rinks are designed for year-round use.

The main spectator rink is a hybrid dimension of 61 metres x 27 metres (200 feet x 90 feet) which is 1.5 metres (5 feet) wider than a standard NHL rink. It has a seating capacity of 2,700 with the ability for future expansion to 3,200 spectators, and can also be used for con- certs, community events, and other spectator events. The main spectator rink features the Huskie men’s and women’s hockey team dressing rooms, team facilities as well as the Huskie men’s and women’s soccer team rooms along with space designated for Campus Recreation. The Community Rink is a 200-seat NHL sized arena that houses dedicated dressing rooms for competitive minor league teams, and 12 additional dressing rooms for minor hockey and campus recreation teams. The total building area is 2,128 square metres (22,915 square feet).

The large two-storey glazed lobby is the focal point of the building, featuring a central reception area, a pro shop, con- cession, and a double gymnasium with twin NBA-sized basketball courts and men’s and women’s team dressing rooms. The upper level includes administration, a sport science and health centre with a high-performance sports research lab, box office, concession and a large lounge with views into the main spectator rink.

The precast concrete components

By Mazen Elmousa

During the initial design phase of the project, the general con- tractor explored metal, cast-in-place concrete and precast concrete options for the structure of the arena seating. Based on past experience, the general contractor understood the benefits of building with precast concrete: versatile design options, off-site production advantages of components produced ahead of time in a controlled environment, and a reduced project schedule because of fast installation at the site.

The decision to use precast concrete also relied on a visit by the general contractor and project stakeholders to the new NHL Rogers Place in Edmonton where the local Lafarge precast concrete plant had supplied all of the precast components. The quality of that project, along with the analysis showing lower overall lifecycle cost of maintaining the building, decided the use of precast concrete.

Lafarge supplied 3,700 square metres (42,000 square feet) of 300 millimetre thick (12 inch) precast concrete hollowcore spanning about 12 metres (39 feet) for the main floor deck of both rinks, 1,630 linear metres (5,348 feet) of precast concrete bleachers, 188 step units and 29 raker walls. All of the precast concrete hollowcore slabs, and the two top rows of bleachers were pre-stressed to take the imposed load from the top cast- in-place slab. All precast concrete components were produced with regular mix concrete, and the bleachers were completed with a smooth finish.

Mazen Elmousa, P.Eng is Engineer, Business Development and Projects Manager at Lafarge Canada Inc. in Saskatoon.

The delivery of the project brought together the University with the general contractor (Wright Construction Western Inc.), the arena operator (Nustadia Recreation), and the design team (aodbt architecture + interior design, Architecture49, and WSP). As additional partners came on board the program evolved from the original 1,500-seat spectator arena, a 200-seat recreation arena, and a modest lobby. The evolving program required a highly collaborative and integrated process to manage the changes while maintaining the schedule and budget.

A large challenge, besides managing the additional program requirements, was engaging a large base of stakeholders and donors on multiple levels in an effort to maximize the fundraising campaign. Significant time was dedicated to identifying and understanding owner, donor, and stakeholder expectations to deliver a design that met their expectations.

The structure is a combination of conventional steel framing and precast concrete, chosen for its cost and speed of construction. Exterior finishes are masonry and metal, and the majority of interior walls are concrete block.

Dallas Huard, SAA, AAA, AIBC, MAA, RAIC is a Partner and Principal Architect with aodbt architecture + interior design in Saskatoon.

PHOTOS aodbt Architecture + Interior Design and Lafarge Canada Inc.

- OwnerUniversity of Saskatchewan

- ArchitectArchitecture49 and aodbt architecture + interior design

- Precast SupplierLafarge Canada Inc.

- EngineerWSP

- ContractorWright Construction Western Inc.

Imagineering Magazine

View our latest issue of the popular Imagineering Magazine.